As soon as we think of vehicles, we think of the engine and the exhaust system as the most important components. While the exhaust and engine are still complex they are not the only systems that make your vehicle operate the way it does.

The suspension is well important too which is highly dependable on two components – tie rod and control arm.

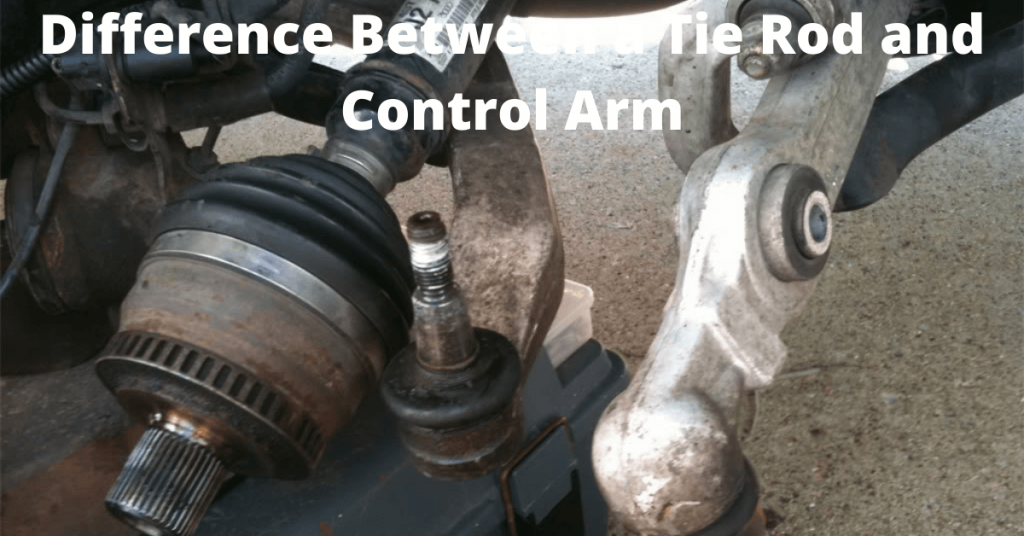

A control arm connects the frame to the suspension while a tie rod connects the rack and pinion to the front wheels. The only similarity between a tie rod and control arm is that both of them work towards connecting two components with each other.

Everything You Should Know About a Tie Rod

What Is a Tie Rod and What Is Its Function?

Changing direction is one of the most fundamental things when it comes to handling any vehicle and a tie rod is the one component that makes this possible. Tie rods are slender cylindrical structures with two sections made of high-strength steel. Tie rods essentially help the steering rack, arm, and wheel work together acting as a pivot point.

Where is the Tie Rod Located?

The tie rod or tie rod ends are each located between the two front wheels at the back of the hub and brake rotor.

Is a Tie Rod Part of a Vehicle’s Suspension?

Since tie rods are part of a vehicle’s steering system this makes them part of the front suspension too. Despite steering and suspension being two separate systems since they work hand in hand, this makes tie rods part of both.

What Kind of Material Are Tie Rods Made Of?

The most commonly used material in the making of tie rods is high-strength steel but you can also find tie rods made of mild steel, aluminum alloy, EN-8, EN-19, and carbon fiber.

What Causes Tie Rods to Go Bad?

A common reason why a tie rod goes bad is the lack of lubrication but there are other reasons too. These include normal wear and tear from everyday use as well as harsh road conditions which can shorten the lifespan of a tie rod. Potholes and bumps in the road are the first things you should avoid as they can easily cause tie rods to go bad if you go over them frequently.

Should I Replace Tie Rods in Pairs?

When the time comes to replace tie rods it’s best that you do so with both the inner and outer rod ends. So, yes you should always replace them in pairs.

Everything You Should Know About a Control Arm

What Is a Control Arm and How Does It Work?

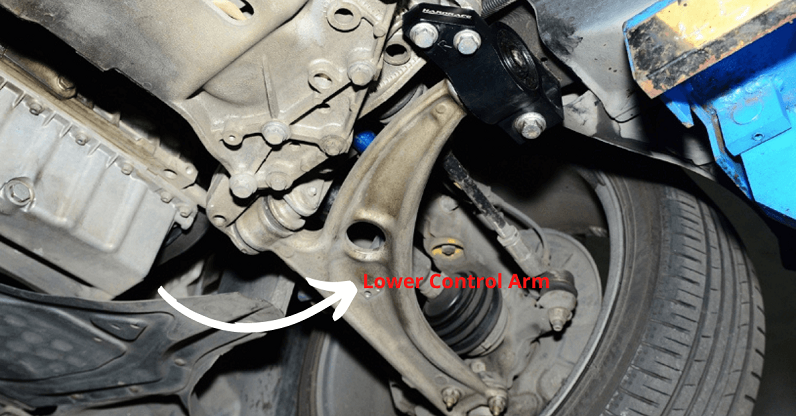

Like tie rods, control arms are also part of the suspension system but they do have a different function and are placed in a different location. Control arms help with the motion of the wheels by keeping them synchronized with the body of the car. Control arms are attached to the chassis and they work together with bushings to reduce friction and restrain other components from moving around.

What Are 2 Types of Control Arms?

The two types of control arms are “A” and “L” shaped control arms. “A” shaped control arms look like a triangle and have the narrow end attached to the wheel’s assembly with the broader end attached to the frame of the car. “A” shaped control arms are one of the most commonly used designs. “L” shaped control arms, on the other hand, connect to the steering knuckle on one end and then pivot on a ball joint on the opposite one. The main difference here is that “L” shaped control arms are a single shaft design.

How Long Do Control Arms Last?

As you would expect, just like every vehicle component, the control arm can get worn or bent as time goes by. Usually, a control arm assembly will wear out anywhere between 90,000 and 100,000 miles. This, of course, goes if normal driving conditions are met, otherwise you can end up wearing out the control arms on your vehicle even faster.

What Are the Symptoms of a Bad Control Arm?

While there are many signs that can indicate a bad control arm, they are not always strictly related to the control arm. There are some signs though that are strong indicators of something being wrong with the control arm. These include tire wear, vibrations, and noises which can also be due to deteriorated bushings. You can also experience steering wandering when there is a bad or failing control arm.

Are Control Arms Hard to Replace?

Control arms are known to be difficult to replace especially if you have the suspension of your vehicle corroded or rusted. This is because the ball joint from the steering knuckle needs to be separated which can be quite tricky. You also need to check the alignment of your car after replacing a control arm.

Is It Ok to Replace Only One Control Arm?

While you don’t have to replace both control arms when one of them has gone bad, when it comes to the usual wear and tear it only makes sense to replace both. Why? Well, because, even if one control arm is not as worn out as the other, it will definitely wear out soon. You don’t want to do the same thing twice when you can do it once, right?

What Happens If the Control Arm Breaks?

When a control arm breaks while driving the bushings will start to absorb the shock from road bumps. You will feel continuous vibration when the control arm is broken or not functioning. Hence why the metal sleeves of the control arm will start to rattle too which will create an annoying clunking that you will hear coming from the front wheels.

Tips to Help You Maintain A Solid Suspension

Rotate & Inflate Tires

Rotating your tires regularly will prevent any uneven wear which if left unattended can end up affecting the performance of your suspension. You should rotate your tires every 18,000 miles. Checking tire pressure and inflating your tires to the level recommended by the manufacturer is a must. This will ensure optimum handling as well as braking performance which both affect the suspension system.

Check Tire Tread

The tread on the tires needs to be above a certain level in order for you to have good control over your vehicle. If the tread on the tires shows uneven wear then your vehicle is in a need of an alignment which if not done on time can affect the suspension.

Inspect The Shocks

The most familiar components of a suspension system are probably the shock absorbers as they are one of the most noticeable suspension components. When there is excessive wobbling and bouncing or an unbalanced feeling when you go into turns it means that there’s something wrong with the shocks. They are most likely damaged and are in need of a replacement. Otherwise, this wouldn’t be happening, which is why you should inspect the shocks regularly.

Inspect Bushings & Joints

Since the majority of components that the suspension system is made of need to be able to move, it’s important to check their various types of linkages connected by flexible connections. These include the bushings and joints as well as bearings. The majority of these linkages are solid metal parts but that doesn’t mean they are invincible.

Also read:

Lubricate Joints

Wherever there are moving parts lubrication is crucial for the longevity of those components. In the case of your vehicle’s suspension, these parts are the joints. The joints help maintain the smooth movement of other components including the steering knuckles and control arms. In a way, all suspension components depend on one another. This is why lubricating joints whenever you do an oil change is important as it’s going to help keep them running for longer and the same goes for your suspension.

Align Wheels

Properly aligned wheels equate to better handling and less tire wear which makes your vehicle safer. Wheel alignment should be done either every 2 years or 30,000 miles but if you drive on rough roads it’s better that you align the wheels even sooner – about every year.

Check Power Steering Fluid & Belt

Checking the tightness of the belt as well as the level of the power steering fluid will help keep your vehicle safe. If you were not to pay attention to these two components you would end up damaging power steering components. It’s important to check the belt and power steering fluid every 5,000 or at every oil change to prevent a slipping belt or low fluid levels. Power steering fluid should be changed about every 30,000 miles.

Avoid Potholes

You should pay attention to your driving skills too in order to keep your vehicle’s suspension working for longer. Avoiding bumps and potholes as much as you can helps minimize the number of impacts your vehicle’s suspension encounters. This way you won’t have to align your wheels as often. You should also avoid going too quickly over speed bumps and if you’re not able to avoid an obstacle on the road, slow down as much as you can to reduce damage to your vehicle’s undercarriage.

Avoid Carrying Unnecessary Weight

While packing your vehicle for a trip is something we all do from time to time, overdoing it can wreak havoc on your vehicle’s suspension especially if you do this often. Don’t ever go over the maximum load-carrying abilities of your vehicle as this will also make your vehicle use more fuel to keep itself running.

Conclusion

Two very undermined vehicle components but also two very important components – this is essentially what the tie rod and control arm are. No matter how well you know your vehicle you will never truly know its capabilities if you don’t understand its suspension system, especially the tie rod and control arm. While these components are found at two different locations in a vehicle they share something in common – connectivity. If it weren’t for the two who knows how vehicles would’ve turned out today.